As a leader in renewable fuel energy,

Introducing an innovative system.

Chamhana Technology Research Institute's

Service solution

Download the

e-brochure.

WASTEF® is a heating catalyst,

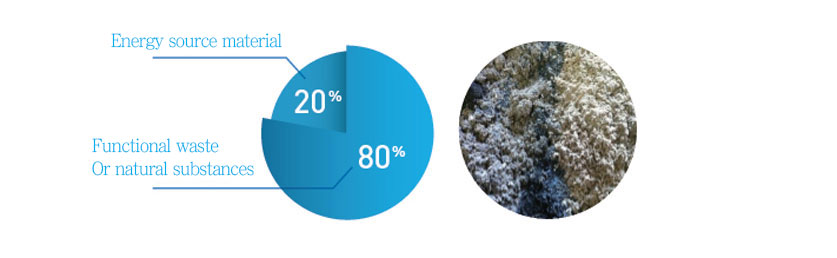

WASTEF® is a heating catalyst, Composition of WASTEF®

| Solid fuel | moisture(%) | Ash (%) | Volatile (%) | Fixed carbon | Calorific value(kcal/kg) | Total sulfur (%) |

|---|---|---|---|---|---|---|

| Moisture | Ash | Vol Mat | Fixed | Caloric value {Dry) | Total s. | |

| 1st analysis | 2.76 | 17.20 | 60.59 | 22.21 | 4,440kcal | 2.90 |

| Secondary analysis | 3.35 | 21.76 | 37.73 | 40.51 | 4,520kcal | 0.62 |

| 3rd analysis | 4.59 | 18.22 | 20.74 | 21.99 | 5,195kcal | - |

* Calorific value analysis organization: Korea Mine Management Corporation, Standard calorific value: 4,400~5,200Kcal/Kg

| division | Current technology | Chamhana New Technology | Remark |

|---|---|---|---|

| Technical name | RDF / RPF technology | True fuelization new technology | |

| Waste treatment/td> |

· RDF: Gun, heatable waste · RPF: Vinyl, plastics |

All waste (Coverage, wet, flammable, non-combustible) |

Current technology can handle only some waste |

| Treatment additive | none |

WASTEF® 100% eco-friendly additive |

Invention patent pending trademark |

| Installation cost | high price | Less than 30% of RDF facility cost |

|

| Fuelization cost | 2 times of coal (LNG level) |

Less than half the coal | |

| Production fuel characteristics |

· RDF: insufficient heat, auxiliary fuel · RPF: Dioxin generation |

Calorie 3500-5500Kcallkg Can be used as main fuel |

|

| Combustion gas | Smoke and harmful gas generation |

Better combustion characteristics than coal Minimizing smoke and harmful gases |

Focal combustion, latent heat combustion And reburn characteristics |

| Landfill | Most of the landfill. (Only some wastes are fueled) |

No landfill required (All waste fuelization) |

Waste that has already been landfilled Fuelable |

| division | Current technology | Chamhana New Technology | Remark |

|---|---|---|---|

| Technical name | Microbial treatment (BIO) method 1) High temperature carbonization treatment method |

True fuelization new technology |

|

| Processing additives |

1) Microbial strain 2) None |

WASTEF® 100% eco-friendly additive |

Invention patent pending trademark |

| Treatment and equipment costs |

High processing and equipment costs |

Less than 20% of current technological facilities and processing costs |

|

| High-temperature carbonization fueling method Fueling cost |

2 times of coal (LNG level) | Less than half the coal | |

| High temperature carbonization fuel type fuel characteristics |

Undercalorie (Caring for calories volatile due to high heat) |

Full fuelization for high calorific value (Average 4500Kcal/kg) |

|

| Bio method problems |

· High processing cost (no economics) · Equipment cost is high · Problems handling residues after treatment · The possibility of microbial mutation |

· Economical · Equipment cost: 20% or less · Does not use any microorganisms, Safely fuels all without treatment residues |