As a leader in renewable fuel energy,

Introducing an innovative system.

Chamhana Technology Research Institute's

Service solution

Download the

e-brochure.

| Applied method | Chamhana Z-AMT water treatment method | ||

|---|---|---|---|

| Processing method | Batch method (5 ton pilot facility) | ||

| Processing period | 72 hours | ||

| Test Institution | pre-treated raw water |

treated water | |

| (1) COD | 435 | 19.8 | |

| (2) BOD | 2,718.00 | 16.5 | |

| Under discharge permit |

COD 50 or less | ||

※ Subject to change depending on site conditions and circumstances

| Item | Calculation result | Calculation | Remark |

|---|---|---|---|

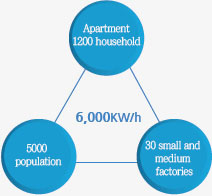

| Total heat generated per hour | 516 million Kcal/h | 6,000Kcal x 360 | Kcal/Kw=860 |

| Total heat generated per hour | 1,300 million Kcal/h | 516 million x 100/40 | Power Generation Efficiency 40% |

| Fuel consumption per hour | 3ton | 1,300 aks 4,500 | - |

| Daily fuel consumption | 80tons | 3 x 24 | 8ton margin |

| Fuel cost per hour | 15,000won | 3 x 500won | True fuel price 50% of coal price 50% |

| Fuel cost per KW | 25won | 150,000/6,000 | 65 won for coal |

| Fuel cost savings (Compared to coal) |

576 million won/day 180 million won/month 2 billion won/year |

True fuel 3x50,000x24- 3.6 million won Coal 3x130,000x24.93 million won Savings 936-360-576 million won |

※ Subject to change depending on site conditions and circumstances

| Item | Calculation result | Calculation | Remark |

|---|---|---|---|

| General electricity purchase | 540,000 won/hour | 6,000KW x @90 | Industrial electricity @90 won/KW |

| Purchase of renewable energy electricity | 1.2 million won/hour | 6,000Kw x @200 | Power Generation Efficiency 40% |

| Additional revenue from the KEPCO |

600,000 won/hour 430 million won/month 5.98 billion won/year |

6,000Kw x @100 | Price difference @110 won |

※ Subject to change depending on site conditions and circumstances

| Item | Calculation result | Calculation | Remark |

|---|---|---|---|

| Total power of power generation | 5.16 million Kcal/hour | 6,000Kcal x 860 | Kcal/Kw=860 |

| The amount of coal equivalent to surplus heat energy (per hour) |

1,290kg | 516,4,000 | - |

| Converted thermal energy price | 12.9 million won | 1,290kg x @100 | Coal price 100 won/kg |

| Heat Sales Revenue |

7. 70,000 won/hour 1.86 million won/day 5,578 million won/month 6.7 billion won/year |

1.29 million won x 0.6 | Heat loss rate 40% |

| Item | Amount (won/year) |

|---|---|

| Fuel cost savings | KRW 200 million |

| Electricity sales difference | 51.8 billion won |

| Heat Sales Revenue | 6.7 billion won |

| total | 78.5 billion won |